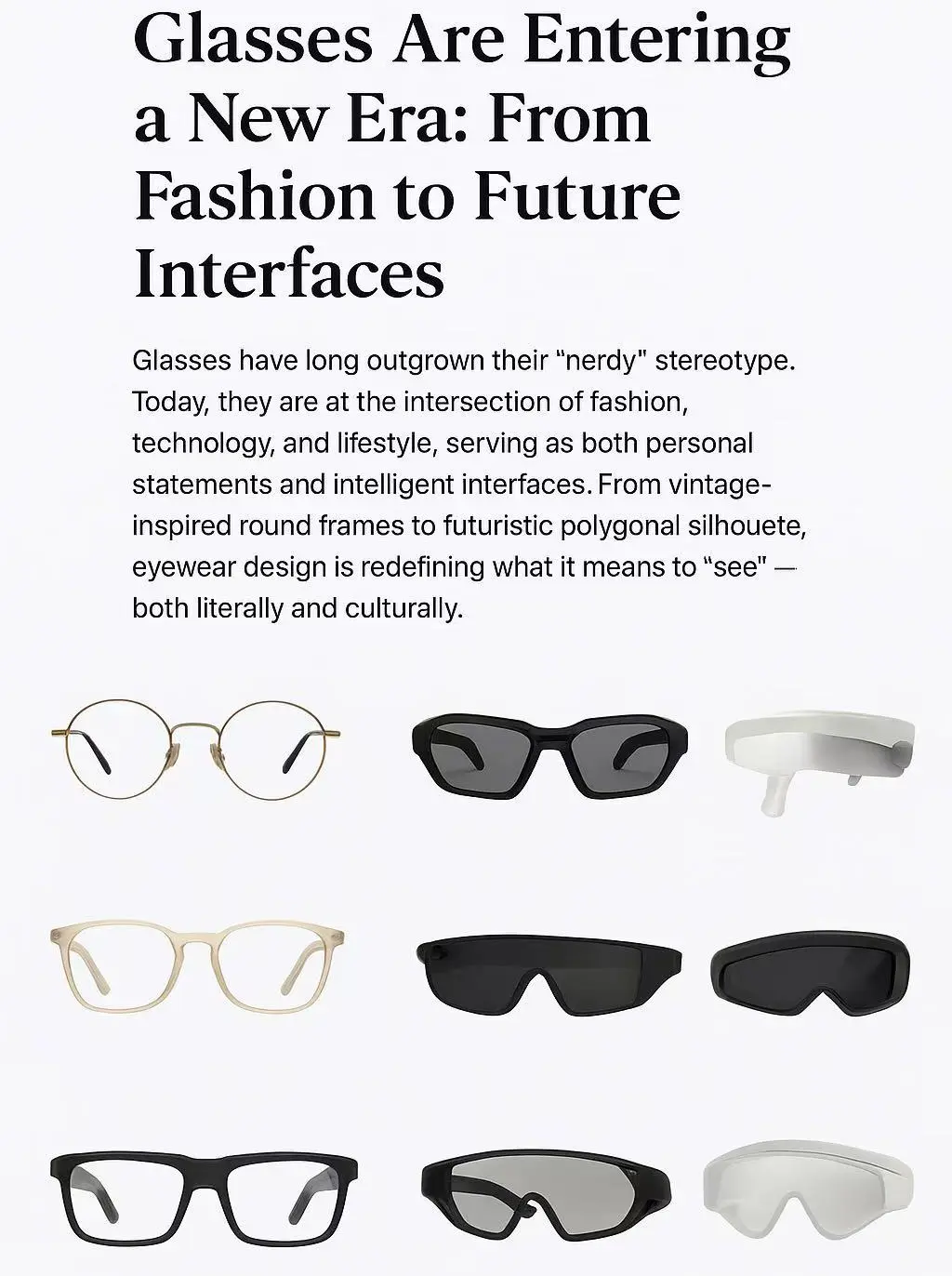

Innovative Eyewear Design with Digital Printing Technology

The eyewear industry has experienced a paradigm shift with the advent of digital printing technology, enabling eyeglass frames to become more than just functional accessories—they are now canvases for unlimited artistic expression. The vibrant and intricate patterns seen on modern eyeglass frames, such as the ones in the image above, are made possible through cutting-edge digital printing techniques.

What is Digital Printing on Eyewear?

Digital printing involves transferring high-resolution designs directly onto the surface of eyeglass frames. This process utilizes advanced inkjet or UV printing technology to embed detailed images, patterns, or colors onto materials such as acetate, polycarbonate, or metal. The precision and versatility of digital printing have opened up a world of design possibilities, allowing for the customization of virtually any pattern, from abstract swirls to photorealistic imagery.

The Advantages of Digital Printing

Unlimited Design Options

Traditional manufacturing techniques, like hand-painting or lamination, impose significant limitations on design complexity and variety. Digital printing, on the other hand, allows manufacturers to print any design imaginable, including gradient colors, holographic effects, and intricate details. This versatility enables designers to cater to a wide range of aesthetic preferences, making eyewear a true reflection of personal style.

High Precision and Consistency

Unlike manual processes, digital printing ensures that every eyeglass frame in a batch is identical, maintaining a consistent quality. This precision is particularly advantageous for large-scale production, as it eliminates discrepancies in patterns or colors.

Sustainability

The digital printing process is eco-friendly compared to traditional methods. It minimizes material waste, uses less water, and requires fewer harmful chemicals, aligning with the growing demand for sustainable manufacturing practices.

Customization at Scale

Digital printing enables mass production and one-of-a-kind designs alike. Customers can personalize their eyeglass frames with unique images, logos, or patterns, creating a level of individuality that was previously unattainable.

The Process

The production process includes the following steps:

Design Creation: Designers craft high-resolution digital files using graphic design software.

Material Preparation: Eyeglass frames are pre-treated to ensure the surface is optimal for ink adhesion.

Printing: Using specialized printers, the design is directly applied to the frame with UV-resistant, durable inks.

Finishing Touches: A protective coating is applied to enhance durability and resistance to wear, ensuring the design remains vibrant over time.

Applications and Market Impact

Digital printing technology has revolutionized not just eyeglass frame aesthetics but also the business model of the eyewear industry. Brands can now offer limited-edition collections and collaborate with artists to produce exclusive designs. This has elevated the status of eyewear from a necessity to a fashion statement, appealing to a younger, trend-conscious demographic.

Additionally, digital printing allows optical stores to offer on-demand customization, providing customers with a truly unique shopping experience. This capability is particularly popular in markets where personalization is a key driver of consumer choice.

Looking Ahead

As digital printing technology continues to evolve, the possibilities for eyewear design are virtually endless. Future innovations may include augmented reality integration, smart designs, and even more sustainable printing materials. With digital printing, the humble eyeglass frame has become a medium for artistic innovation and personal expression, reshaping the way we perceive eyewear in fashion and functionality.

Please contact us if you are interested.